We have been developing clamping systems of high quality and precision for over 30 years. Already in the planning and development of expansion shafts, expansion mandrels, expansion chucks and friction shafts we rely on know-how and professional competence.

Many years of experience, technical know-how and adherence to delivery dates distinguish us as a high-performance partner in clamping technology.

Information on the prices of our products is available on request.

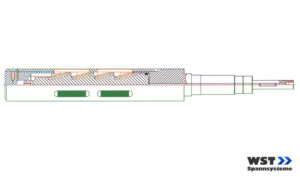

Read morepneumatically actuated

Depending on bale weight, bale width and torque, the support tube is equipped with a number of independently operating clamping elements.

The filling valve fills the internal rubber hose with approx. 6 bar air so that the clamping elements are pressed outwards. In order to prevent the various types of cores from slipping through, clamping elements made of different materials with longitudinal or transverse grooves are used.

The support tube can also be made of steel, aluminium or carbon fibre reinforced plastic.

The SZX mandrel is available for winding cores with an inner diameter of 50-150 mm. On request, this mandrel is also available in other dimensions.

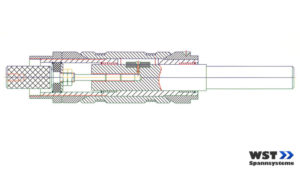

pneumatically actuated

This mandrel is designed as a rolling axis. The braked roll is unwound by means of the web tension. The roll is tensioned by means of external clamping jaws. Power is transmitted pneumatically with permanent air supply via a rotary distributor. Axial adjustment is possible by means of the right knurled screw.

This mandrel is designed as a rolling axis. The braked roll is unwound by means of the web tension. The roll is tensioned by means of external clamping jaws. Power is transmitted pneumatically with permanent air supply via a rotary distributor. Axial adjustment is possible by means of the right knurled screw.

The SDZ mandrel is available for winding cores with an inner diameter of 70-400mm. On request, this mandrel is also available in other dimensions.

mechanically expanding, pneumatically actuated

This mandrel is designed as a rolling axis. The braked roll is unwound by means of the web tension. The roll is tensioned by means of external clamping jaws. Power is transmitted pneumatically with permanent air supply via a rotary distributor. Axial adjustment is possible by means of the right knurled screw.

This mandrel is designed as a rolling axis. The braked roll is unwound by means of the web tension. The roll is tensioned by means of external clamping jaws. Power is transmitted pneumatically with permanent air supply via a rotary distributor. Axial adjustment is possible by means of the right knurled screw.

mechanically expanding